Silicon Carbide (SiC) Processing for Devices

SiC-based power electronics offer several advantages over conventional Si devices, which include: (1) operation at higher electric fields and higher temperatures with better reliability than Si-based power electronics due to a wide bandgap (3.3 eV for 4H-SiC); (2) improved thermal conductivity (3X that of Si), which enables higher power density packaging for SiC devices with better heat dissipation; and (3) superior saturation electron velocity (2X that of Si) allows for higher frequencies of operation with lower switching losses than Si-based power devices. The physical properties of SiC make it preferred for the development of electronic devices, including power MOSFETs with high blocking voltage and low on-resistance and Schottky barrier diodes (SBD) that can withstand large breakdown fields with small reverse leakage currents.

Silicon carbide is grown as a boule: a large, nominally single-crystal cylinder. The boule is sliced into thin substrate wafers, which are polished. Epitaxial layers are grown on the substrate. The typical polytype that is grown for power electronic applications is 4H-SiC. The substrates are typically sliced 4º off of the c-axis. During epitaxy growth, an initial buffer layer is used to reduce defect propagation from the substrate, and the full epitaxy is then grown to be a few microns thick.

Defect inspection is used at every step of the wafer production process to qualify the processing steps, feed forward defect information for die mapping, and feed back killer defect densities for yield improvement.

Epilayer Defects

Defects in the epilayer of SiC are most directly correlated with device failures. These defects are typically seeded by a crystallographic defect or particle downfall at the substrate surface. For instance basal plane dislocations (BPDs) in the substrate have the potential to convert into killer defects in the epitaxy such as stacking faults (SFs) or epitaxy BPDs.

Conventional methods for detecting epitaxy defects include surface scatter imaging and photoluminescence (PL) imaging. Many killer defects such as BPDs and SFs, are not visible in surface channels. High-throughput PL imaging, which measures bulk PL, can see subsurface defects, but it cannot distinguish between types of SFs and polytype inclusions.

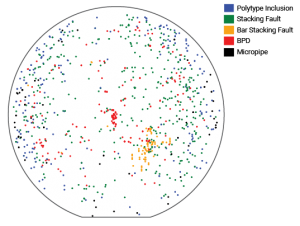

In the figures below we show how Ultrafast Imaging is not only able to detect all killer epilayer defects, but the Transient Absorption (TA) channel is also able to classify triangular defects. Based on signal intensity TA can distinguish polytype inclusions, more-killer SFs (such as Shockley SFs), and less-killer SFs (such as intrinsic Frank SFs). Because TA is sensitive to how defects impact band structure, the brightest defects are the most likely to be killer! We are able to record 3D volumetric images of those features to see defect origins, morphology, and to visualize defect clusters.

Substrate Defects

For making devices in SiC, defects of interest in SiC substrates are primarily crystallographic defects that propagate, including dislocations, stacking faults (SFs), and micropipes (MPs). Highly localized defects such as point defects and voids are sometimes interesting, but less critical if they will not propagate into an epitaxial killer defect. Within the set of dislocations there are threading-screw dislocations (TSDs), threading-edge dislocations (TEDs), and threading-mixed dislocations (TMDs), all of which exist along the crystallographic c-axis. Basal plane dislocations (BPDs) exist in the basal plane, normal to the c-axis. Substrate manufacturers are expected to quantify the density of each of these defects to grade wafers, and to help predict eventual device yield on the wafer.

The current standard methods for substrate defect detection are KOH etch and X-Ray Topography (XRT). KOH etch is a standard for detection of TSDs, TMDs, TEDs, and BPDs, but it is a destructive and slow method. It is therefore only applied to a sample of wafers sliced from the boule. XRT is a standard for TSD and TMD detection and the measurement of BPD density. Because XRT cannot currently detect TEDs with sufficient contrast, it has not replaced KOH etch, but because it is non-destructive XRT may be applied to more wafers.

Ultrafast microscopy methods that have been pioneered by MONSTR Sense are well suited to optically detect substrate defects. Optical methods are the preferred inspection option because they are fast and non-destructive. Ultrafast microscopy uses an ultrafast laser as an illumination source and a variety of detection channels including Transient Absorption (TA), Linear Absorption (LA), and Polarized Linear Absorption (PLA) to detect defects. Data fusion algorithms use data from each of these channels to identify and classify threading dislocations, BPDs, SFs, and MPs.

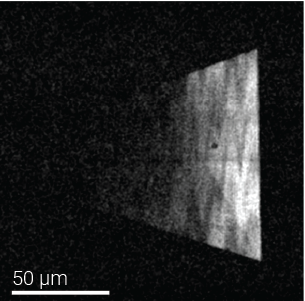

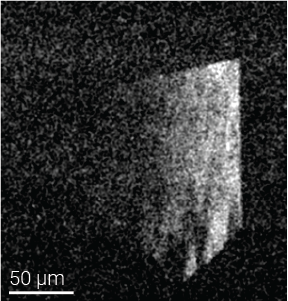

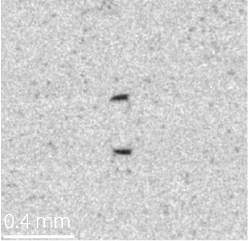

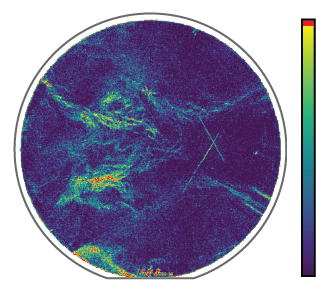

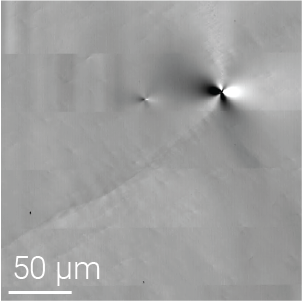

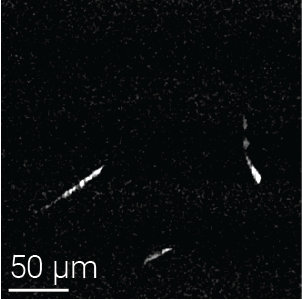

In the figure below, a map of TED and TMD density of a full wafer is plotted in a). Detection algorithms detect the individual defects, and the density is calculated from those detections. Image b) reveals a high-contrast MP in the PLA channel, and many lower contrast features lined up in a row, which corresponds to a TED cluster. Image c) shows BPDs detected using the TA channel.

a) TED and TMD density map

b) TEDs (low contrast) and micropipes (high contrast)

c) BPDs in SiC Substrate

What makes Ultrafast Imaging so powerful?

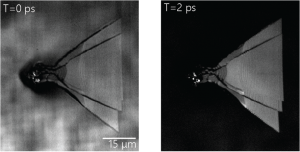

Ultrafast lasers create an excitation in semiconductors at a timescale that is nearly instantaneous compared to all physical relaxation processes within the material. The excitation is deterministic, and the time scale of relaxation processes becomes a source of defect contrast. For instance, an excitation of bulk SiC relaxes almost instaneously, while defect areas containing trapped states will have decay times on a much longer timescale. In the adjacent figure we show that using a TA measurement tuned to a finite decay time, ultrafast imaging offers a background-free measure of select defects in SiC.

Ultrafast lasers create an excitation in semiconductors at a timescale that is nearly instantaneous compared to all physical relaxation processes within the material. The excitation is deterministic, and the time scale of relaxation processes becomes a source of defect contrast. For instance, an excitation of bulk SiC relaxes almost instaneously, while defect areas containing trapped states will have decay times on a much longer timescale. In the adjacent figure we show that using a TA measurement tuned to a finite decay time, ultrafast imaging offers a background-free measure of select defects in SiC.

For More Information check out the MONSTR Sense poster from the International Conference on Silicon Carbide and Related Materials (ICSCRM) 2025:

Testers, advisors, feature recommendations, and more needed

If you have an interest or are an expert in silicon carbide or device manufacturing, please reach out to us. We are actively working to improve defect inspection in silicon carbide, and we can use your help. Let’s start with a call!

Related links

Product page:

KRAKEN BLUE Turnkey Ultrafast Microscope

Automated turnkey ultrafast microscope for characterizing & inspecting defects in wide bandgap semiconductors. KRAKEN BLUE microscope supports 6″ and 8″ wafers.

Product page:

Compound Semiconductor Inspection Service (CSIS)

Characterize your full compound semiconductor wafers or test out the efficacy for your needs of our inspection equipment with our analytical testing service.

Product page:

PERISCOPE Colocalization and Visualization Software

Software for colocalization and visualization of measurements acquired using different tools. Quickly align and overlay various tool measurements with defect data from KLARF file.